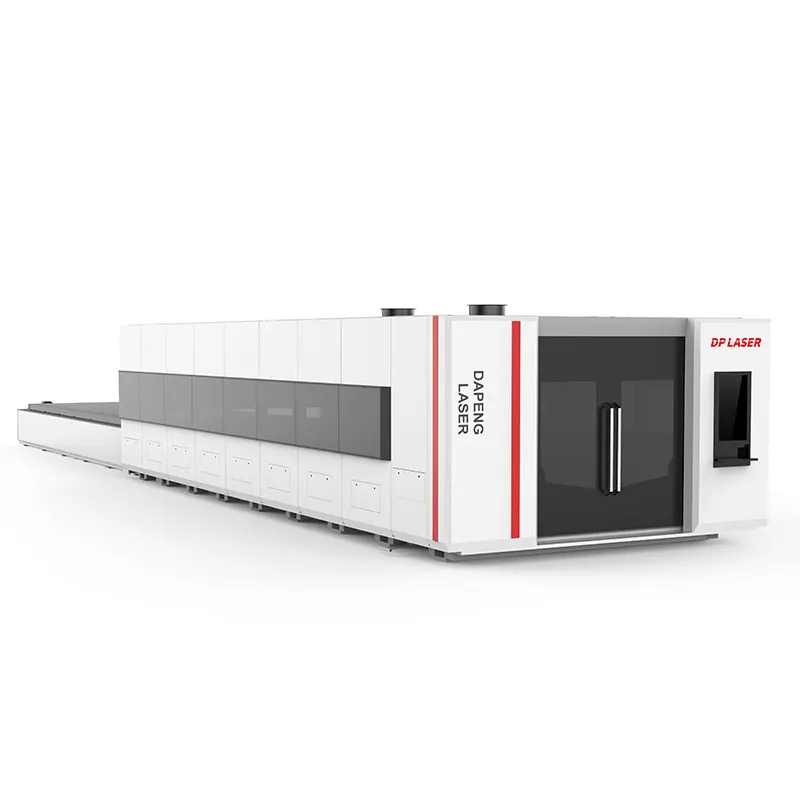

H8025D-Exchange Table Fiber Laser Cutting Machine With Whole Cover

The H8025D-Exchange Table Fiber Laser Cutting Machine With Whole Cover is designed for high-efficiency, high-precision cutting of sheet metal. This advanced machine features a unique exchange table system with a fully enclosed protective cover for increased safety and smooth operations. With its powerful fiber laser and cutting-edge technology, the H8025D provides excellent cutting capabilities for a wide variety of materials including stainless steel, carbon steel, and aluminum, making it ideal for industries like automotive, aerospace, and heavy manufacturing.

Key Features

- Whole cover exchange table for seamless material handling

- High-performance fiber laser for clean, precise cuts

- Advanced control system for optimal cutting performance

- Fully enclosed design for enhanced safety and operator protection

Detailed Description

The H8025D-Exchange Table Fiber Laser Cutting Machine With Whole Cover features a unique exchange table system that allows for quick and seamless material changes. This system eliminates downtime between cutting cycles, enabling continuous production without interruptions. The exchange table design enhances workflow efficiency, reduces operator involvement in material handling, and significantly boosts productivity, making it ideal for high-volume manufacturing environments.

Equipped with a high-performance fiber laser, the H8025D provides superior cutting precision and speed. The fiber laser technology offers a finely focused laser beam, which delivers clean, smooth cuts with minimal heat-affected zones. This reduces material distortion and improves cutting quality, ensuring consistent results for a wide range of materials such as stainless steel, aluminum, and carbon steel. The fiber laser also minimizes the need for post-processing, contributing to cost savings and reduced lead times.

The advanced control system of the H8025D ensures optimal cutting performance by allowing for precise adjustments to cutting parameters. The system’s intuitive interface simplifies operation, enabling operators to easily set up and monitor the machine. The sophisticated software integrates real-time data, providing precise control over cutting speeds, power levels, and other key parameters. This control system allows for high precision cutting while maintaining operational efficiency.

Safety is a priority in the H8025D-Exchange Table Fiber Laser Cutting Machine With Whole Cover. The machine features a fully enclosed protective cover that shields operators from the high-intensity laser beam and other cutting hazards. The enclosure also prevents the emission of harmful smoke and dust, ensuring a cleaner and safer working environment. The safety systems include emergency stop buttons and sensors that halt operations in case of an emergency, further enhancing the safety of the machine during operation.

The H8025D is built with a robust and durable structure designed to withstand high-intensity operations. The machine’s frame and components are engineered to provide stability and maintain high precision cutting over long periods. The precision linear guides and rack and pinion systems ensure smooth and accurate movements of the cutting head, minimizing wear and tear and maximizing the lifespan of the machine. The sturdy construction ensures that the machine remains stable even during high-speed cutting operations, reducing vibration and increasing cutting accuracy.

Designed for ease of use, the H8025D includes automated features that streamline the cutting process. The automatic material loading and unloading system reduces the need for manual handling, improving operational efficiency and minimizing the chances of human error. The system automatically detects the thickness and type of material, adjusting the cutting parameters accordingly for optimal results. This feature makes the H8025D highly adaptable to a wide variety of projects, increasing its versatility in different industrial applications.

The H8025D-Exchange Table Fiber Laser Cutting Machine With Whole Cover is ideal for industries that require high precision, speed, and versatility. Its advanced features make it perfect for applications in the automotive, aerospace, and manufacturing sectors, where quality and efficiency are critical. The machine’s ability to handle both small and large-scale production jobs with minimal downtime and maximum precision ensures that businesses can meet the demanding requirements of modern manufacturing.