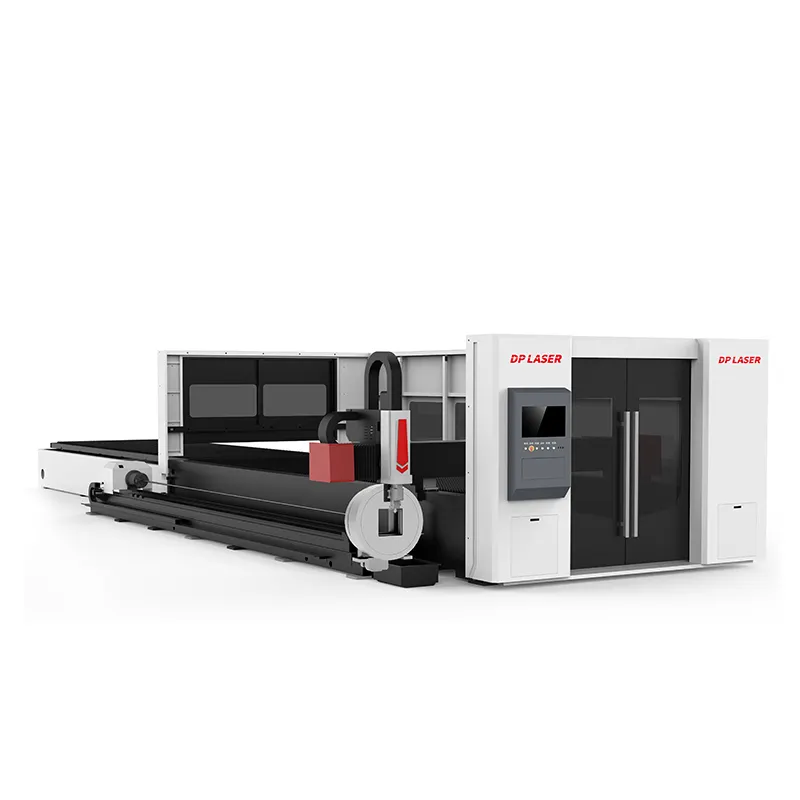

H6020DF-Tube And Sheet Metal Whole Cover Exchange Table Fiber Laser Cutting Machine

The H6020DF-Tube And Sheet Metal Whole Cover Exchange Table Fiber Laser Cutting Machine is designed for industries that require efficient and precise cutting of both tube and sheet metal. With its unique whole cover exchange table system, this machine ensures seamless material handling, reducing downtime and increasing overall productivity. The integration of advanced fiber laser technology ensures high cutting speeds and precision, making it an ideal choice for a wide range of applications, from automotive to structural steel fabrication.

Key Features

- Whole cover exchange table for fast material switching

- High-precision fiber laser cutting technology

- Automatic material handling for optimized workflow

- Energy-efficient operation with minimal maintenance

Detailed Description

The H6020DF-Tube And Sheet Metal Whole Cover Exchange Table Fiber Laser Cutting Machine features a whole cover exchange table, which allows for quick and efficient material switching. This innovative design eliminates the need for manual intervention during material changes, significantly reducing downtime and improving overall productivity. The exchange table ensures that both tube and sheet metal can be processed without interruption, making it ideal for high-volume manufacturing environments where efficiency is key.

Equipped with advanced fiber laser cutting technology, the H6020DF delivers high precision and fast cutting speeds. The fiber laser beam is finely focused, ensuring minimal heat-affected zones and reducing the risk of warping or distortion. The machine can handle a variety of materials, including stainless steel, carbon steel, and aluminum, with consistent results. The high precision of the cutting process ensures clean, accurate cuts with minimal material waste, improving production efficiency and quality.

The H6020DF-Tube And Sheet Metal Whole Cover Exchange Table Fiber Laser Cutting Machine is designed with an advanced automated material handling system. This system optimizes the workflow by automatically loading and unloading materials without manual intervention. The result is a seamless, uninterrupted cutting process that improves throughput and minimizes human error. The automation ensures that production runs smoothly, reducing the time spent on material handling and increasing the overall efficiency of the cutting operation.

Energy efficiency is a key benefit of the H6020DF machine. The fiber laser technology used in this system consumes less energy compared to traditional CO2 lasers, while still providing the high performance required for fast and precise cutting. This energy-efficient operation translates to lower operational costs, making the H6020DF a cost-effective solution for industries that need to balance high production output with minimal energy consumption. The machine’s efficient design also minimizes the need for regular maintenance, further reducing long-term costs.

The H6020DF is built for durability and reliability, ensuring stable performance over long production runs. Its robust frame and high-quality components ensure the machine can withstand the demands of continuous operation in industrial environments. The machine is equipped with a precision guide system, which ensures accurate positioning during the cutting process, and high-performance servo motors that enable fast and smooth movement. This combination of advanced technology and solid construction makes the H6020DF ideal for industries that require high-speed, high-precision cutting with minimal downtime.

Maintenance is simplified with the H6020DF-Tube And Sheet Metal Whole Cover Exchange Table Fiber Laser Cutting Machine’s easy-to-access design and self-lubricating system. The machine is built with high-quality components that are designed to last, and the modular structure allows for easy replacement of parts when necessary. The automated lubrication system ensures that critical components, such as the guide rails and bearings, remain well-maintained without the need for manual lubrication. This reduces the likelihood of breakdowns and keeps the machine running at peak performance for longer periods.

Safety is a top priority with the H6020DF. The machine is equipped with a fully enclosed protective cover that ensures operators are shielded from the cutting area, preventing exposure to harmful laser radiation and debris. The machine also includes a variety of safety sensors, such as emergency stop buttons and motion sensors, which ensure that the cutting process is halted immediately in case of any irregularities. These safety features protect both the operator and the machine, ensuring a safe working environment and reducing the risk of accidents.