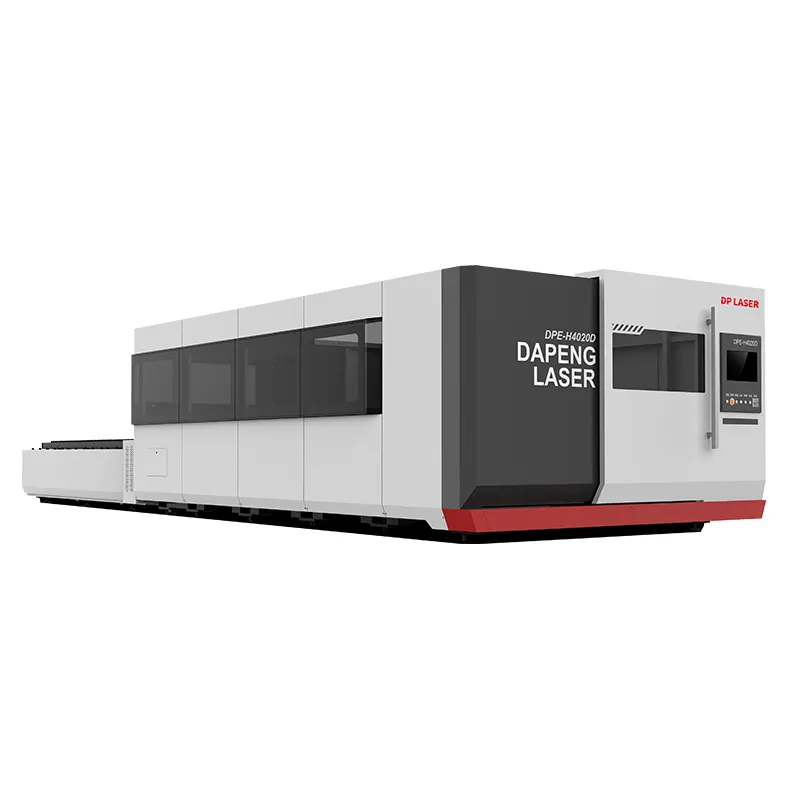

4020DH-Whole Cover Exchange Table Metal Sheet Fiber Laser Cutting Machine

The 4020DH-Whole Cover Exchange Table Metal Sheet Fiber Laser Cutting Machine is designed to provide high-efficiency cutting for metal sheets in industrial applications. Featuring a whole cover exchange table system, this machine reduces downtime by allowing for seamless material handling. With high-speed fiber laser technology, it delivers precision cuts on a variety of metal materials, including stainless steel, carbon steel, and aluminum, making it an ideal solution for industries such as automotive, aerospace, and metal fabrication.

Key Features

- Whole cover exchange table system for fast material switching

- High-speed fiber laser technology for efficient cutting

- Energy-efficient design with reduced power consumption

- Fully enclosed protective cover for enhanced safety

Detailed Description

The 4020DH-Whole Cover Exchange Table Metal Sheet Fiber Laser Cutting Machine features a whole cover exchange table system, which enables quick material changes, reducing downtime between cutting cycles. This dual exchange table design ensures that while one table is in use for cutting, the other can be loaded or unloaded, enhancing production efficiency and streamlining workflows in high-volume industrial environments.

Equipped with a high-performance fiber laser, the 4020DH delivers precise cuts with minimal heat-affected zones. The fiber laser technology focuses a powerful beam onto the material, resulting in clean, smooth edges and high-quality cuts. This ensures minimal material distortion, which is crucial for industries that require tight tolerances and high precision, such as aerospace and automotive manufacturing.

With cutting speeds of up to 110 meters per minute, the 4020DH provides high-speed performance, allowing for faster production and increased throughput. The machine’s ability to cut through a wide range of materials, including stainless steel, carbon steel, and aluminum, with minimal waste makes it an efficient and cost-effective solution for manufacturers looking to optimize their production processes.

The 4020DH is designed with energy efficiency in mind. Compared to traditional CO2 laser systems, the fiber laser technology used in this machine consumes less power, resulting in lower operational costs and a more sustainable solution. This energy-efficient design not only reduces electricity consumption but also minimizes the machine's environmental impact, making it a more eco-friendly choice for modern manufacturing.

Safety is a key feature of the 4020DH. The machine is equipped with a fully enclosed protective cover that ensures operator safety during operation. The protective cover prevents exposure to the high-intensity laser beam and shields the operator from any debris or smoke generated during the cutting process. The inclusion of safety sensors, emergency stop functions, and fire-resistant materials enhances the overall safety of the machine, making it suitable for use in industrial environments with stringent safety requirements.

Built with reliability in mind, the 4020DH is constructed with high-quality components and a robust frame that ensures stable operation even during long production runs. The machine’s advanced cooling system ensures that the laser remains at optimal performance levels, preventing overheating and extending the machine’s lifespan. The precision guide and servo motor system enable smooth, accurate movements, ensuring cutting precision across a range of materials and thicknesses.

The 4020DH-Whole Cover Exchange Table Metal Sheet Fiber Laser Cutting Machine is ideal for industries that require high-precision, high-speed cutting, including automotive, aerospace, and metal fabrication. Its ability to handle a wide variety of materials and thicknesses, combined with its high-speed capabilities and energy-efficient design, makes it an essential tool for modern manufacturing operations. The machine’s advanced safety features and robust construction ensure that it can meet the demands of both small and large-scale production environments.